(1)

M. Rulandus

(2)

T. Tiffereau

(3)

R. Hunter

(4)

A. Waite

(5)

Fulcanelli

(6)

F. Jollivet-Castelot

(7)

S. Emmens

(8)

C. Lea

(9)

J. Champion

(10)

References

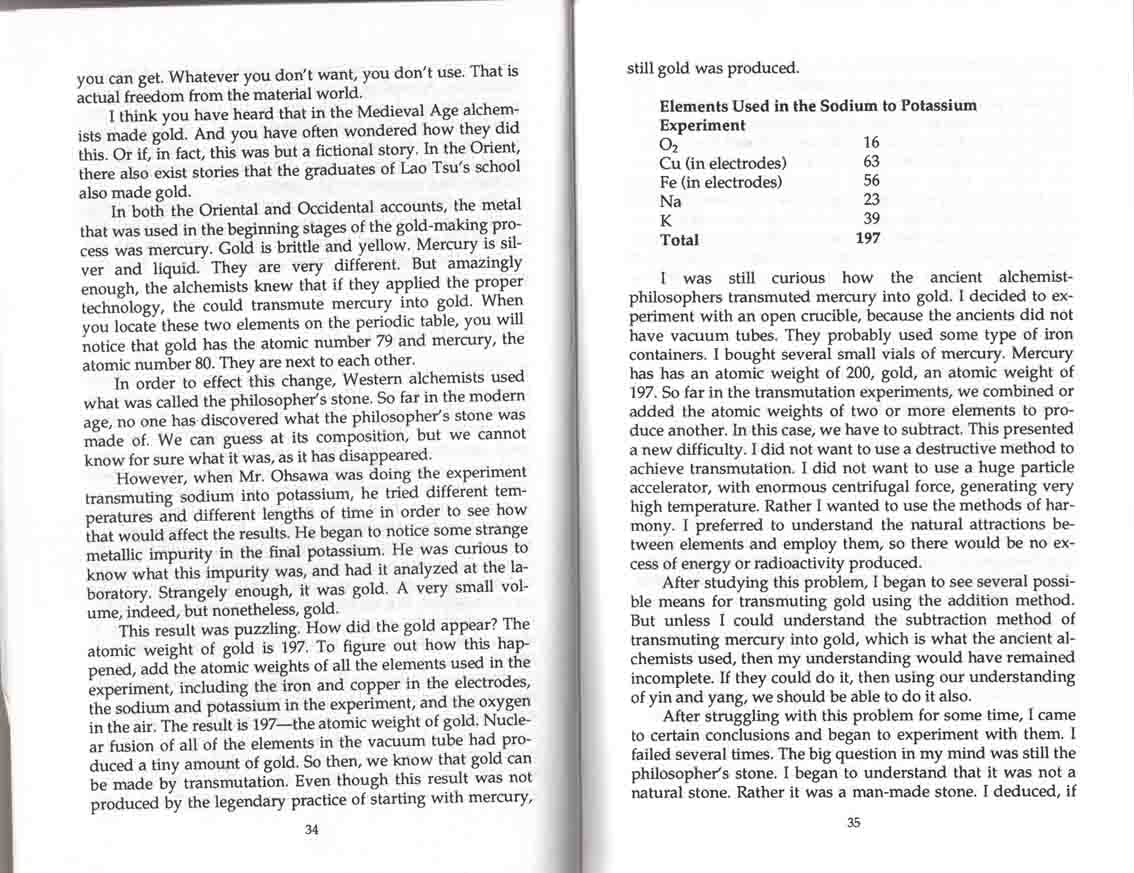

Gold can be manufactured

from other elements by several methods. The

transmutation of silver to gold is the least difficult

to accomplish. The methods developed by Francois

Jollivet-Castelot offer a good chance of success, albeit

with great danger due to the use of arsenic. The

penultimate means of transmutation is the Philosophers'

Stone of any degree, but that is another matter

altogether.

Fulcanelli and others Adepts,

however, affirm that experiments such as these are not

Alchemy, but rather "hyper-chemistry" or "archymy". The

following procedures are included in this collection in

order to afford a wider perspective to all inquirers,

and to console those who fail to complete the Ars Magna.

Most of the 19th and 20th

century experimenters in this genre used a variety of

"wet" techniques (refluxing with nitric acid, etc.), or

"dry" transmutations with alloys in the furnace. Dr.

Stephen Emmens used high-pressure hammering (500

tons/sq. in.) of silver at low temperature, followed by

fluxing, granulation, more hammering, treatment with

"modified nitric acid", and refining.

(1)

Martin Rulandus ~ A Lexicon of Alchemy

Gold --- Its

Artificial Production ~ It is not only by the

common operations of mining and digging in the

profundities of the earth that it is possible to obtain

Gold. It is quite within the powers of Art to imitate

Nature in this matter, for Art perfects Nature in this

as in many other things. We propose to provide in this

place an account of a formal experiment, the worth of

which has been tested over and over again, and has in

fact become little less than familiar among operators in

the pursuit of the Grand Work. In order to perform it a

large crucible must be provided, and it must be of such

a quality as will be able to resist the action of

intense heat. This crucible must be set over a burning

furnace, and at the bottom of the vessel there must be

strewn Powder of Colophony (a kind of resin) to about

the thickness of the little finger. Above this undermost

layer there must be another layer of Fine Powder of Iron

--- that is, the Finest Iron Filings --- which shall be

of the same thickness. Subsequently, the filings must be

covered with a little Red Sulphur. Then the fire in the

furnace must be increased till the iron filings have

passed into a liquid condition. The next operation is to

throw in Borax --- that kind which is made use of by

goldsmiths for melting gold. To this must be added a

like quantity of Red Arsenic, and as much Pure Silver as

will be equivalent to the weight of the Iron Filings.

Let the entire composition undergo coction by driving

the furnace, taking care at the same time not to inhale

the steam, on account of the arsenic in the vessel. Take

then another crucible into which, by inclining the first

vessel, you must pour the cocted matter, having

previously stirred it effectually with an iron spatula.

Proceed in such a manner that the composition will flow

into the second crucible in a purified state, and devoid

of recremental matter. By means of the Water of

Separation, the Gold will be precipitated to the bottom.

When it has been collected, let it be melted in a

crucible, and the result will be good Gold, which will

repay all pains and expense which have been devoted to

its production. This chemical secret is contained in the

‘Hermetic Cabinet’, and the facility with which the

experiment can be performed has led many persons to

undertake it. The authority cited in support of it is no

less than that of the most learned Basil Valentine, who

also affirms that the operation of the Grand Work of the

Philosophers can be performed in less than three or four

days, that the cost should not exceed three or four

florins, and a few earthen vessels are sufficient for

the whole experiment.

(2) Theodore

Tiffereau

Between 1854-55, Theodore

Tiffereau submitted six memoirs to the French Academie

des Sciences concerning transmutations of silver to

gold. He published a compilation of the papers ( Les

Metaux sont des Corps Composes ) in 1855.(25-27)

Tiffereau conducted his

experiments at considerable expense while supporting

himself making daguerotypes in Mexico. Tiffereau claimed

that Mexican silver possesses peculiar qualities that

lend to its augmentation as gold (Dr. Emmens also used

Mexican silver in his work). While he claimed success in

principle, he made no capital gains. Tiffereau

demonstrated his process at the French Mint in Paris

before the assayer M. Levol, but the results were

unsatisfactory.

Tiffereau attempted many

modifications of his techniques, and claimed that

certain experimental conditions influence the

transmutation of silver to gold:

1) Pure silver filings were

used, sometimes mixed with pure copper filings (Ag 9:1

Cu) and traces of zinc, iron, alumina and silica;

2) Trace amounts of gold

catalyze the reaction;

3) The silver was refluxed with

concentrated nitric acid, hyponitrous acid, and nitrogen

protozide or deuteroxide;

4) Concentrated sulfuric acid

was used at times;

5) The acids were exposed to

sunlight to "solarize" them. Tiffereau complained that

the French sun was not so effective as the Mexican;

6) Halides and sulfur in the

presence of oxides of nitrogen improved the reaction,

and so did ozone;

7) Prolonged reaction time

increased yields.

Tiffereau attributed the

production of gold in the earth to the action of the

"microbe of gold". This was confirmed in the 1980s by

the discovery that placer gold nuggets form around a

nucleus of bacillus cereus.

The following experiment is

typical of Tiffereau's general methods:

"After having exposed, over two

days, pure nitric acid to the action of solar rays, I

added pure silver filings with pure copper filings in

the proportions of the alloy of money (9:1). A lively

reaction manifested, accompanied with a very abundant

deposit of intact filings agglomerated in a mass.

"The disengagement of nitrous

gas continued without interruption, and I left the

liquid as is over twelve days. I noted that the

aggregate deposit was augmented sensibly in volume. I

then added a little water to the dissolution in which

the product had precipitated, and again abandoned the

liquid to rest five days. During this time, new vapors

unceasingly disengaged.

"The five days having passed, I

raised the liquid just to ebullition, which I maintained

until the nitrous vapors ceased disengagement, after

which I evaporated it to dryness.

"The matter obtained from the

dessication is dry, dull, blackish-green; it did not

offer an appearance of crystallization...

"Placing the matter again in

pure nitric acid and boiling six hours, I saw the matter

become clear green without ceasing to aggregate in small

masses. I added a new quantity of pure concentrated

nitric acid and boiled it anew; it is then that I

finally saw the disaggregated matter take the brilliance

of natural gold...

[The third test in this series]

"presented an extraordinary phenomenon to be noted: the

quantity of the alloy that I used experienced a

transformation entirely to pure gold."

Carey Lea suggested that

Tiffereau and other experimenters had merely prepared a

gold-colored form of allotropic silver.

(3) R. M.

Hunter

In 1908, Sir Henry Baskerville

made mention of a contemporary claim to the production

of artificial gold:

"Among the many communications

reaching the writer, one is of more than passing

interest. Mr. R.M. Hunter, of Philadelphia, has written

concerning 'synthetic gold' as follows:

"I have so perfected the

process that in my judgment, based on my actual

experience, gold may be manufactured at enormous profit,

and to this end I have designed a plant to be erected in

Philadelphia and am at this moment negotiating for

$500,000 capital for its erection. I realize that the

public and most scientific men are adverse to the belief

in the possibility of such an enterprise, but I know

what I am doing and can afford to allow public sentiment

to follow its own course.

"Enclosed with the letter was

an affirmative affadavit. On request, Mr. Hunter

promptly forwarded me samples of silver in which the

gold is 'growing' and some 'grown-up' gold, said to have

been produced by his secret process. I have not made

analyses of the samples." (5)

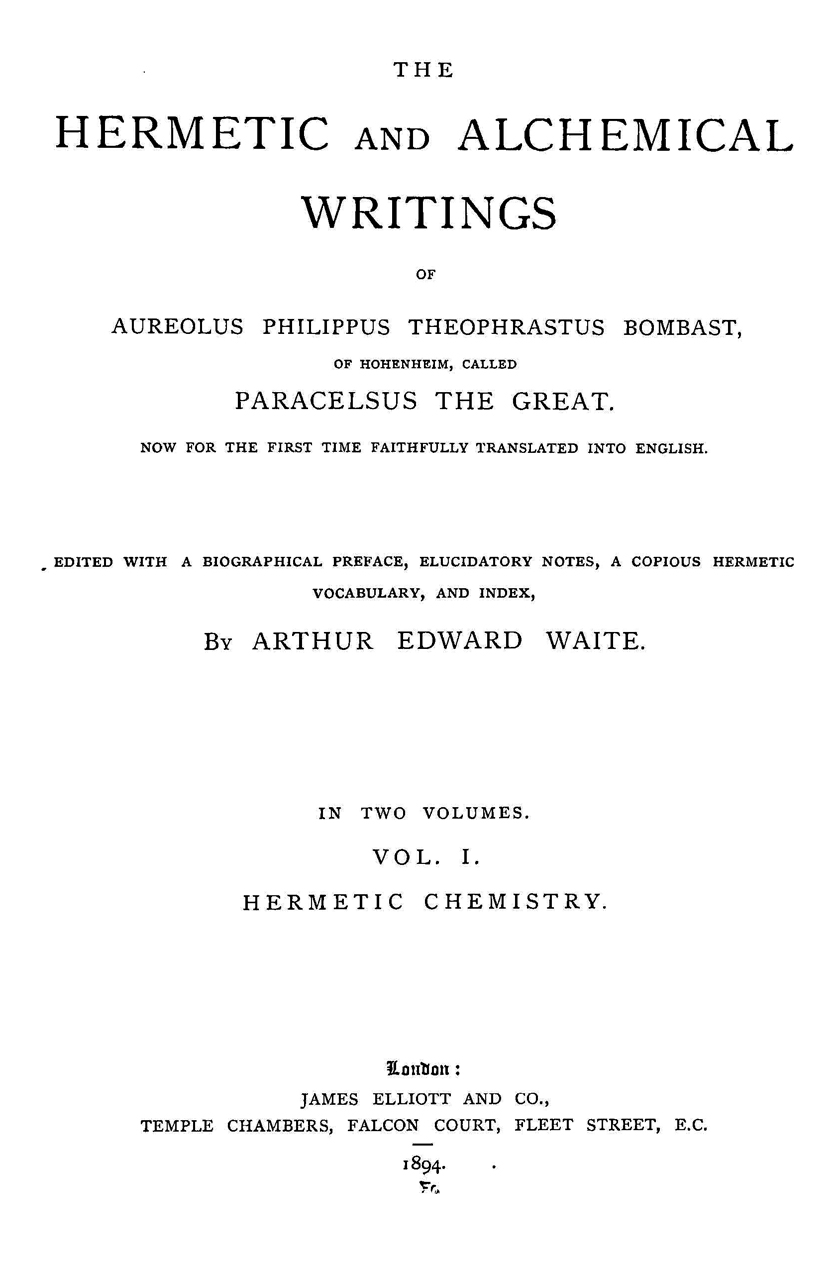

(4) Arthur E.

Waite

The eminent occultist Arthur E.

Waite wrote A Collection of Alchymical Processes

which includes a segment entitled "Silver Transmuted

Into Gold By The Action Of Light":

"In the focus of a

Burning-Glass, 12 inches in diameter, place a glass

Flask, 2 inches in diameter, containing Nitric Acid,

diluted with its own volume of water:

"Pour into the Nitric Acid,

alternately, small quantities of a Solution of Nitrate

of Silver and of Muriatic acid, the object being to

cause the Chloride of Silver to form a minutely divided

state, so as to produce a milky fluid, into the interior

of which the brilliant convergent cone may pass, and the

currents generated in the Flask by the Heat may so drift

all the Chloride through the Light.

"The Chloride, if otherwise

exposed to the Sun, merely blackens on the surface, the

interior parts undergoing no change: This difficulty,

therefore, has to be avoided. The Burning-Glass promptly

brings on a decomposition of the salt, evolving, on the

one hand, Chlorine, and disengaging a metal on the

other. Supposing the experiment to last two or three

entire hours, the effect will then be equal to a

continuous midday sun of some 72 hours. The Metal

becomes disengaged very well. But what is it? It cannot

be silver, since Nitric acid has no action on it. It

burnishes in an Agate Mortar, but its reflection is not

like that of silver, for it is yellowish, like that of

Gold.

"The Light must therefore have

so transmuted the original silver as to enable it to

exist in the presence of Nitric Acid." ( 28)

(5) Fulcanelli

The renowned master Fulcanelli

published this transmutation of silver in Les

Demeures Philosophales:

"The simplest alchemic

procedure consists in utilizing the effect of violent

reactions --- those of acids on the bases --- to provoke

in the midst of the effervesence the reunion of pure

parts, their new arrangement being irreducible. In this

manner, starting from a metal close to gold ---

preferably silver --- it is possible to produce a small

quantity of the precious metal. Here is, in this order

of research, an elementary operation whose success we

guarantee, providing the instructions are carefully

followed.

"Empty into a glass retort,

tall and tubular, one-third of its capacity in pure

nitric acid. Adapt to the receiver an escape tube and

arrange the apparatus in a sand bath.

"Gently heat the apparatus

short of reaching the boiling point for the acid (83o

C). Turn off the fire, open the tube, and introduce a

small portion of virgin silver, or of cupel, free from

gold traces. When the emission of peroxide of azote has

stopped and when the effervesence has quieted, let drop

into the liquor a second portion of pure silver. Repeat

introducing metal, with no hurry, until the boiling and

issuing of red vapors manifest little energy, which is

indicative of the property of saturation. Add nothing

more. Let it rest for half an hour, then cautiously

decant your clear solution into a beaker while it is

still warm. You will find a thin deposit in the form of

black sand. Wash this with lukewarm water, and let it

fall into a small porcelain capsule. You will recognize

by making the assays that the precipitate is insoluble

in hydrochloric acid, just as it also is in nitric acid.

Aqua regia will dissolve it and yields a magnificent

yellow solution, exactly like gold trichloride. Use

distilled water to dilute this liquor; precipitate from

a zinc blade. An amorphous powder will be obtained, very

fine, matte, of reddish brown coloration, identical to

that given by natural gold reduced in the same manner.

Wash well and dessicate this pulvurent precipitate. By

compression on a sheet of glass or marble, it will give

you a brilliant, coherent lamina with a beautiful yellow

sheen by reflection, green by transparence, having the

look and superficial characteristics of the purest gold.

"To increase with a new

quantity this miniscule deposit, you may repeat the

operation as many times as you please. In this case,

take up again the clear solution of silver nitrate

diluted from the first washing water; reduce the metal

with zinc or copper. Decant this silver into a powder

and use it for your second dissolution." (14)

(6) Francois

Jollivet-Castelot

Francois Jollivet-Castelot was

the Secretary General (and later President) of the

Alchemical Society of France (founded in 1896). He also

edited the Society's journal L'Hyperchemie, and

served as a special delegate of the Supreme Council of

Martinists. He authored several books and articles on

alchemy and "hyperchemistry", a system of non-occult

chemical methods of transmutation. (17-20)

Jollivet-Castelot began

experimenting with transmutations of silver in 1908. In

1920, he published La Fabrication Chimique de L'Or

to report his successes using both "wet" and "dry"

methods of transmutation:

"By means of catalytic action I

have succeeded in manufacturing gold chemically by

acting on silver with arsenic and antimony sulfides,

tellurium, and tin.

"This process gives a very high

yield which has already been confirmed by several

chemists, in particular by Mr. Ballandras, Chemical

Engineer of Lyons, and Mr. Outon, Chemical Engineer of

Buenos Aires...

"The object of the present

leaflet is to enable chemists to repeat and check my

experiments in their turn...

"I made a mixture composed of 3

gr of chemically pure silver and 1 gr of chemically pure

orpiment and placed it in 36o nitric acid for

several months cold and then brought it to ebullition.

The liquid was kept at the boiling point for several

days. A small quantity of the material became detached

at this moment and formed a pulvurent black deposit.

When no further action took place, I decanted off the

solution and collected the insoluble residue. This

residue was attacked by aqua regia at the boiling point

until it was almost completely dissolved; the liquor

when decanted and filtered was analyzed and gave all the

characteristic reactions for gold.... [December 1925]

"I acted on 22 gr of chemically

pure silver ... and on 3.5 gr of chemically pure

orpiment... The mixture was heated to about 1600o

C In a metal smelting furnace for about three quarters

of an hour. The residue obtained was again melted with

the addition of orpiment. After having hammered for half

an hour and remelted with the addition of small

quantities of orpiment every ten minutes, it was

withdrawn.

"After cooling and the addition

of chemically pure antimony sulfide, it was again put

back into the furnace, small quantities of orpiment

being thrown in every five minutes. The residue obtained

had a dark metallic tint. After hammering it became

slightly golden.

"The residue dissolved in

chemically pure 36o nitric acid first cold

and then hot, gave an abundant pulvurent deposit. This

deposit after being washed and treated with ammonia to

dissolve the arsenic and antimony salts was completely

dissolved in aqua regia. The liquor then being

chlorinated and filtered was subjected to the reagents

of platinum and gold. Mr. Andre Vandenberghe who was

acting as preparator for this experiment, had thought

that in accordance with the law of the evolution of

matter, the transmutation of bodies into gold should be

preceded or accompanied by their transmutation into

platinum...

"The reactions of gold were

quite characteristic; the reactions of platinum also

seemed to reveal its presence.

"The quantity of gold obtained

in this experiment was about one gramme.

"I submit the hypothesis that

the arsenic acts as a catalyst and the sulfur as a

ferment in this transmutation." (December 1925; Douai,

France)...

"As a sequel to my previous

work on the artificial synthesis of gold, I have

introduced tin into these new tests as it is also often

associated with gold in Nature. The following is a

description of this new process, thanks to which the

percentage of gold obtained destroys all the objections

that are raised with regard to impurities.

"I made an intimate mixture of

6 gr of chemically pure silver... 2 gr of antimony

sulfide, 1 gr of orpiment, and one gr of tin... I then

added the usual fluxes and then heated the whole in a

crucible in the furnace to about 1100o C for

about one hour, twice adding a small quantity of SbS.

"The residue obtained was

treated for a long time in 36o nitric acid,

first cold and then at the boiling point; the insoluble

residue was next washed with distilled water, treated

with ammonia, washed again and finally treated for a

long time with boiling aqua regia.

"The liquor when filtered and

subjected to the reagents of gold showed the presence of

this metal in the form of abundant deposits which may be

estimated at 0.05 gr in all, which is very high

considering the 6 gr of silver employed. The deposits

when collected and dried had a yellow green metallic

color and possessed all the characteristics of gold...

"The addition of tin to the

other bodies has certainly facilitated the reactions of

the gold and increased the yield of this metal which can

be manufactured artificially by my process, i.e., by

synthesis and in measurable quantities.

"It would be very easy to show

that, given the respective prices of gold and of the

other substances that are used in my process to produce

it, a profit could be obtained if the process were

worked industrially, all the more so as the greater part

of the silver employed can be recovered at each test..

"I believe I now hold the key

to the regular and even industrial manufacture of gold.

"But the industrial question is

voluntarily put aside from my thoughts, for my only

object is the search for pure scientific truth."

In a correspondence to

Jollivet-Castelot, Mr. Ballandras reported on "How I

Succeeded In Making Gold According To The Process of Mr.

Jollivet-Castelot: Dosage of gold obtained by the second

method":

"From a mixture of 10 gr

silver, 3 gr of tin, 3 gr of arsenic sulfide, and 3 gr

of antimony sulfide, the residue which had been obtained

was crushed as much as possible and subjected to a

treatment of pure chloric acid like in the first method.

However, in order to completely eliminate the silver and

the tin employed, I scrupled to begin again the

indicated treatments, that is as much to say that the

powder which was obtained having been subdued first to

the action of azotic acid, then washed with distilled

water, then subdued to the action of chloric acid, then

washed with distilled water, then once more washed with

distilled water, and these different operations were

begun once again with another portion of pure chloric

acid... The insoluble residue was subdued to the

prolonged action of aqua regia...

"It must be noted that this

thing happened during the ebullition. The washed residue

contained the slighter part of gold; this thing would be

found dissolved in the last liquor which I obtained.

"After 18 hours of digestion at

about 25o, I subdued the mixture to

ebullition during 3 hours. After refrigeration, I

filtered on glass wool and I looked if parts were not

drawn along in suspense. I found nothing. Then, I

decided to proceed to a circumstantial analysis of the

liquor which I obtained...

"The quantity of gold which was

obtained was 0.476 gr for 10 gr of silver employed, or

0.0476 gr of gold per gram of silver."

Jollivet-Castelot read this

memorandum to the Academie Royal des Sciences (Belgium)

on June 6, 1926:

"A Recent Experiment In

Transmutation --- All my research work on

transmutation since 1908 has started from the fact that

gold is found in nature associated with antimony and

arsenic sulfides as well as with tellurium, which is

considered as a mineralizer of gold. I therefore

considered that it was logical to introduce tellurium

into the artificial combination of silver and arsenic

and antimony sulfides that I make...

"I prepared a mixture composed

of 6 gr of silver, 1 gr of native orpiment free of gold,

1 gr of antimony sulfide and 2 gr of tellurium... I

added pure silica to the usual fluxes. This mixture was

heated in the furnace in the usual way for one hour at

about 1100o C. The residue obtained was of a

blackish-grey color with violet reflections. It weighed

6.42 grams.

"When subjected to the action

of nitric acid, the residue was attacked with difficulty

and greenish metallic particles become detached. The

solution was then decanted and a greenish-yellow residue

remained which was kept at the boiling point of nitric

acid for several hours. After decanting off the liquor

once again, the residue, which had not changed, was

washed, treated with ammonia and then subjected to the

action of boiling aqua regia in which it was entirely

dissolved after boiling for several hours.

"[The solution was chlorinated

and subjected to the reagents of gold with positive

results, although] a certain amount of gold was

certainly lost in this test just as in all my previous

tests, for it is known that arsenic, antimony, and

tellurium entrain gold in their fusion and their

volatilization.

"In order to obviate this

disadvantage, I had thought of making the vapors of

arsenic acid and antimony sulfides and of tellurium act

on the silver in fusion in a closed vessel by means of a

special device...

"I consider it certain that if

the vapors were allowed to bubble through the melted

silver, a much higher yield of gold would be obtained

than that I have obtained hitherto by an imperfect and

too rapid contact of the bodies in presence, while it is

undoubtedly necessary to make them react on one another

in the vapor state in a closed vessel."

Mr. Louis Outon, a

pharmaceutical chemist in Buenos Aires, reported to

Jollivet-Castelot in a letter (July 26, 1927):

"Dear Sir... I have repeated

the experiments... in my laboratory and am amazed at the

results. For the moment, it is only the scientific side

which interests me, since the cost of the gold obtained

is often greater than the value of the metal..."

Mr. A. Ballandras also

replicated the experiments and reported the results:

"I will not conceal the fact

that I have often heard ironical remarks aboutprocesses

by which he succeeded in manufacturing gold. I

determined to check his tests with the greatest possible

accuracy...

"In a new quartz crucible, I

placed 15 gr silver, 6 gr arsenic sulfide, 6 gr antimony

sulfide. The crucible was heated at a temperature of 500o

C and then for one hour and a half at 1100o

C. At this moment the mass was fairly liquid... The

crucible was then allowed to cool down. The

reddish-brown residue obtained weighed exactly 23.742

gr, or a loss of 3.258 grams.

"I allowed this residue to cool

in pure nitric acid in which the greater part was

dissolved fairly easily. After prolonged boiling the

liquor was filtered on a new glass wool. The resultant

liquor was very clear and absolutely free of any

particles.

"The glass wool was then

macerated in aqua regia rich in hydrochloric; after 18

hours maceration, the whole was boiled for 3 hours. I

again filtered on glass wool in order to separate any

traces of the filter from the liquor... Any gold that

might have been obtained would necessarily be found in

the last liquor... It was of importance to prove its

existence qualitatively at least.

"For this purpose, I tried the

various standard reagents, the results being the

following: 1) Oxalic acid: flakey precipitate; 2) Iron

sulfate: glossy metallic black; 3) Tin chloride: peach

pink precipitate; 4) Formol: rather light bluish

coloration; 5) Sodium carbonate, potassium carbonate:

light coloration after boiling; 6) Sodium hydroxide,

potassium hydroxide: yellowish coloration, cloudy.

"These reactions are

sufficiently characteristic and clearly prove the

existence in the last liquor of a metal which, even if

it is not gold, must nevertheless be placed very close

to the latter... the metal obtained and gold must be

perfectly isotopic.

"I have repeated this test

several times and I have observed: 1) That the

production of gold is a function of the rapidity with

which the necessary heat is obtained; 2) That it is also

a function of the degree of tightness of the crucible. A

crucible that is closed as tightly as possible gives

better results; 3) That the amount of gold obtained was

not always uniform; some of the tests were absolutely

sterile and I inferred that this was due to some defect

in the mounting.

"I think there must be a

certain temperature that should not be exceeded and that

the external conditions of pressure and electricity must

be of considerable importance."

In another experiment,

Ballandras used silver (10 gr), tin (3 gr), orpiment (3

gr), and antimony sulfide (3 gr):

"After having operated as

previously, I obtained a quantity of gold corresponding

to 0.05 gr per gram of silver employed... This I

consider to be a highly interesting result."

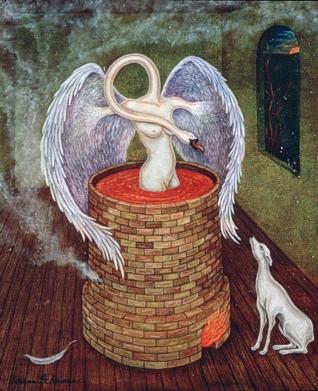

Francois Jollivet-Castelot

(7) Dr. Stephen

Emmens

Early in 1897, the British

chemist Stephen H. Emmens, then residing in New York,

announced the discovery of a new element which fills the

"vacant space existing in the sub-group of Group I", and

which he thought to be the intermediate matter from

which silver and gold are formed. Dr. Emmens said:

"Our claim is that the element

in question is therefore neither silver nor gold, but

which may, by our new physical methods, be converted

into gold." (14)

In 1897, Dr. Emmens'

Argentaurum Laboratory on Staten Island produced over

660 ounces of gold from silver and sold it to the U.S.

Assay Office. He revealed a few historical and technical

details of his transmutation process in his book,

Argentaurum Papers #1: Some Remarks Concerning

Gravitation:

"Our work, which converts

silver into gold, had its origin in the course of

certain investigations which I undertook for the purpose

of preparing chemically pure nickel... in 1892. In

attempting to prepare these pure metals [nickel and

iron], a certain product was obtained which seemed to

differ from anything recorded in the textbooks. The same

product was subsequently found when the investigation

was extended to the case of metallic cobalt... The

phenomena observed afforded indications of the existence

of some substance common to the whole of the elements in

what is known as Series 4 of Group 8 of the

classification of Chemical Elements... It appeared to us

almost self-evident that if we were right in supposing a

common substance to be present in any single series of

elements, the same would hold good for each group.

"And as Group I of the

classification contains the precious metals --- gold and

silver ~ it was obvious that our time and attention

should be directed to these metals rather than to any

other...

"Our starting point, so far as

silver and gold were concerned, was afforded by the

remarkable discoveries of Mr. Carey Lea with regard to

[colloidal silver]... It was found that... this

subdivision of metallic silver was attended by very

considerable changes in the physical properties of the

substance...By certain physical methods and by the aid

of a certain apparatus, we succeeded in bringing about a

further subdivision of the silver. We were not surprised

to find that the substance obtained differed so far from

ordinary silver that it could no longer be regarded as

the same elementary substance. It seemed to require a

new name and a new chemical symbol. Inasmuch, therefore,

as our theory was that this substance was common to both

gold and silver, and in reality was the raw material out

of which both gold and silver were constructed by the

hand of nature, we named the substance Argentaurum...

"The next step was to ascertain

whether this substance could be so treated as to be

grouped into molecules of greater density than those of

silver... We found that... Argentaurum can be aggregated

into molecules having a density considerably superior to

that of ordinary gold molecules. Whether we are right as

to this or not, the condensed Argentaurum presents the

appearance and is endowed with the properties of

ordinary metallic gold...

"We do not consume any

chemicals and other costly materials in our process;

what we use is mainly energy in some of its various

forms, such as heat, electricity, magnetism, gravity,

cohesion, chemical affinity, x-rays and the like... Our

chief source of expense is the time required for

bringing about the desired molecular changes... One

ounce of silver will produce three-quarters of an ounce

of gold..." (6)

Herbert Fyfe reported that Dr.

Emmens' process comprised five stages: 1) mechanical

treatment; 2) fluxing and granulation; 3) mechanical

treatment; 4) treatment with a "modified nitric acid",

and 5) refining. Dr. Emmens said:

"I regard the mechanical

treatment as the causa causans. The fluxing and

granulation serve, I think, merely to render the

molecular aggregate susceptible of displacement and

rearrangement." (15)

The mechanical treatment was

accomplished by means of Dr. Emmens' "Force Engine",

which exerted pressures in excess of 500 tons/in2

at very low temperatures. Step 4, using "modified nitric

acid", contradicts the statement made elsewhere, that

"we do not consume any chemicals... in our process."

(4, 7-12, 15, 16, 23)

Dr. Emmens included a sample of

Argentaurum and these instructions in a letter (21 May

1897) to Sir William Crookes:

"Take a Mexican dollar and

dispose it in an apparatus which will prevent expansion

or flow. Then subject it to heavy, rapid, and continuous

beating under conditions of cold such as to prevent even

a temporary rise of temperature when the blows are

struck. Test the material from hour to hour, and at

length you will find more than the trace (less than one

part in 10,000) of gold which the dollar originally

contained."

Sir Crookes was unable to

replicate the experiment to his satisfaction. He

reported:

"A specimen of Argentaurum sent

me by Dr. Emmens has been examined with the

spectrograph. It consists of gold with a fair proportion

of silver and a little copper. No lines belonging to any

other known elements, and no unknown lines, were

detected."

This analysis resembles that of

ordinary bullion gold, which contains silver and copper

to make it harder and more fusible than pure gold.

In a rejoinder, Dr. Emmens

noted:

"I have received a letter from

a very eminent Fellow of the Royal Society informing me

that he has performed the crucial experiment suggested

in my letter of May 21, 1897, to Sir William Crookes.

The gold contained in the Mexican dollar after 40 hours

of intense cold and continuous hammering was found to be

20.9% more than the quantity of gold contained in the

same dollar before the test."

In 1898, Emmens floated the

Argentaurum Company, a syndicate which promised that for

one ounce of silver (then worth about 50 cents)

entrusted with payment of $4.50 per ounce for conversion

costs, the investor would be repaid with 3/5 ounce of

gold (then worth about $11). Dr. Emmens' application for

a patent on his process was refused, however, so

production never began, since he would not have been

able to protect his methods from unscrupulous

competitors. (24, 29, 30)

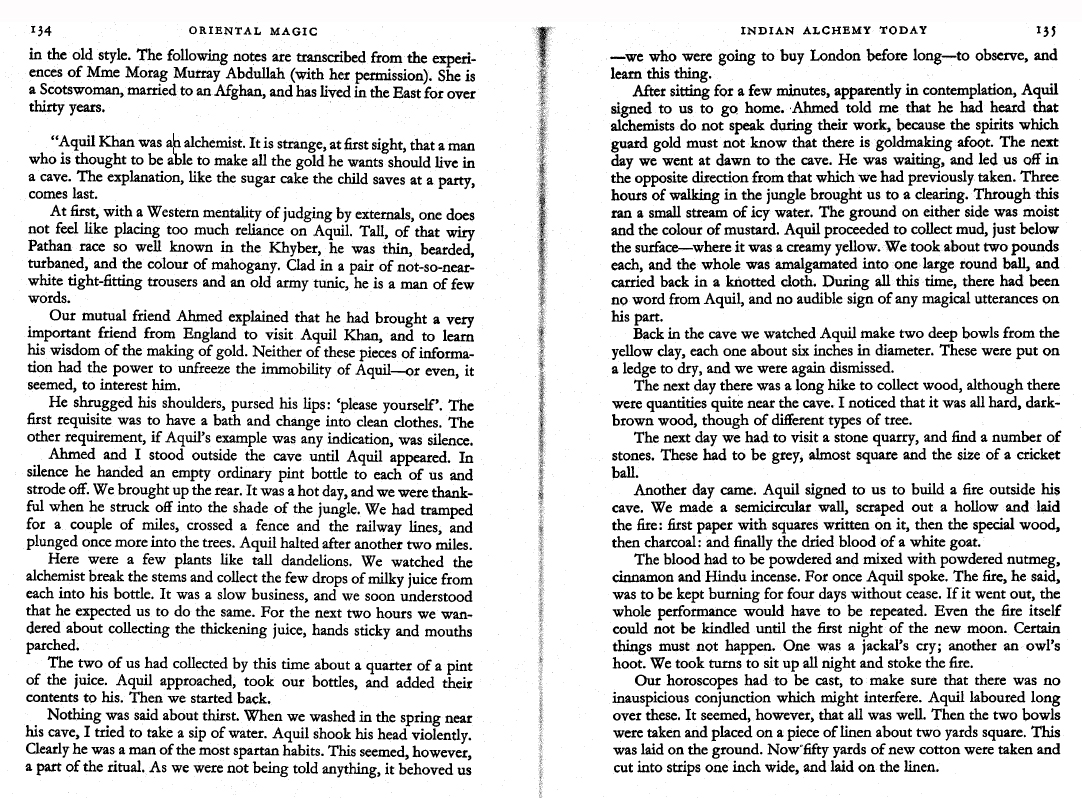

Dr. Emmens was issued several

U.S. Patents for inventions; at least two of them may be

related to his process: #501,996 (25 July 1893),

Electrolytic bath; and #501,997 (25 July 1893),

Apparatus for Electrolytic Extraction of Metals. Dr.

Emmens' Force Engine produced hammering pressures in

excess of 500 tons/in2 at very low

temperatures. These effects can be achieved by a variety

of modern methods.

Semantic ambiguities in Dr.

Emmens' writings confuse the understanding of the

process. At times, Argentaurum refers to a new element,

or to the gold produced from it, or to Lea's

intermediate allotropic silver.

(8) Carey Lea

Carey Lea discovered the

preparation of so-called "allotropic" and "intermediate"

silver in 1889 while he was studying reductions of

silver nitrate. "Allotropic" is a misnomer, however. In

1925, Dr. Richard Zsigmondy, Professor of Chemistry at

the University of Göttingen, received the Nobel Prize in

Chemistry for his study of Lea's "allotropic" silver

under the ultramicrosope. Dr. Zsigmondy found that such

silver actually was a monoatomic colloid of ordinary

silver, not another isotope.

Lea determined that silver

occurs in "allotropic", "intermediate", and ordinary

forms. Ordinary silver is protean in nature. The aqueous

solutions are colloidal monoatoms, and give perfectly

clear solutions. The several forms of "allotropic"

silver (a-Ag) dry with their particles in optical

contact with each other, thus forming continuous films

that are beautifully colored, perfect mirrors. Strong

acids and pressure will convert a-Ag to the normal form.

There are three forms of a-Ag, and all are unstable.

(21, 22)

There is also a very stable

"intermediate form" of silver (i-Ag) which is easy to

prepare. It occurs as bright gold-yellow or green

crystals with a metallic luster. Treatment with a very

dilute solution of ferric chloride will enhance the

appearance of its foliar structure, interpenetrating

with plant-like ramifications, or fine acicular crystals

up to 1 inch long.

Intermediate silver is hard,

tough, and unaffected by pressure. It is nearly as

indifferent to oxidizing and chlorizing agents as is

normal silver. Intermediate silver can be formed from

the allotropic varieties by light, heat, or chemical

action. The simplest preparation is as follows:

"It has long been known that

golden-yellow specks would occasionally show themselves

in silver solutions, but could not be obtained at will

and the quantity thus appearing was infinitesimal.

Probably this phenomenon has often led to a supposition

that silver might be transmuted into gold. This yellow

product, however, is only an allotropic form of silver,

but it has all the color and brilliancy of gold, a fact

which was apparent even in the minute specks hitherto

obtained...

"It is a little curious that

its permanency seems to depend entirely on details in

the mode of preparation. I have found many ways of

obtaining it, but in a few months the specimens

preserved changed spontaneously, to normal silver... The

normal silver produced in this way is exquisitely

beautiful. It has a pure and perfect white color like

the finest frosted jewelers' silver, almost in fact

exceeding the jeweler's best products. I found, however,

one process by which a quite permanent result could be

obtained... the following proportions give good results:

"Two mixtures are required: No.

1 containing 200 cc of a 10% solution of silver nitrate,

200 cc of 20% solution of Rochelle Salt [Sodium

potassium tartrate] and 800 cc of distilled water. No.

2, containing 107 cc of a 30% solution of ferrous

sulfate, 200 cc of a 20% solution of Rochelle salt and

800 cc of distilled water. The second solution (which

must be mixed immediately before using only) is poured

into the first with constant stirring. A powder, at

first glittering red, then changing back to black,

falls, which on the filter has a beautiful bronze

appearance. After washing it should be removed whilst in

a pasty condition and spread over watch glasses or flat

basins and allowed to dry spontaneously. It will be seen

that this is a reduction of silver nitrate by ferrous

sulfate...

"Although the gold-colored

silver (into which the nitrate used is wholly converted)

is very permanent when dry, it is less so when wet. In

washing, the filter must be kept always full of water;

this is essential. It dries into lumps exactly

resembling highly polished gold...

"If we coat a chemically clean

glass plate with a film of gold-colored allotropic

silver, let it dry, first in the air, then for an hour

or two in a stove at 100o C, and then heat

the middle of the plate carefully over a spirit lamp, we

shall obtain with sufficient heat a circle of whitish

gray with a bright, lustrous golden ring round it,

somewhat lighter and brighter than the portion of the

plate that has not been changed by heat. This ring

consists of what I propose to call the "intermediate

form"...

"With sulfuric acid diluted

with four times its bulk of water and allowed to cool,

an immersion of one or two seconds converts a film on

glass or on pure paper wholly to the intermediate

form...

"Its properties are better seen

by using a film formed on pure paper, one end of which

is heated over a spirit lamp to a temperature just below

that at which paper scorches. The change is sudden and

passes over the heated portion of the surface like a

flash. Examining the changed part, we find:

1st. That it has changed from

a deep gold to a bright yellow gold color.

2nd. When subjected to a

shearing stress it does not whiten or change color in

the slightest degree.

3rd. It is much harder, as is

readily perceived in burnishing it.

4th. It no longer shows the

color reaction with potassium ferricyanide and ferric

chloride, changing only by a slight deepening of color.

"Of these characteristic

changes the second is the most remarkable. The

gold-colored silver in its original condition changes

with singular facility to white silver; almost any

touch, any friction, effects the conversion...

The intermediate form is

distinguished from normal silver almost solely by its

bright yellow color and its higher luster."

(9) Joe

Champion

In 2004, Joe Champion

presented a non-toxic method to convert microscopic

amounts of silver to gold by the action of phonons:

"In the formation of Ag (or

other elements) from a dimensional reaction, the

conversion will occur without excess energies or nuclear

signatures. By heating Ag to a temperature of 43.2° C.

The principle is straightforward and simple without

toxicity, by utilizing a heat source that is stable and

capable of heating in the range of 100-120° C. Allow the

temperature of the silver to stabilize at 43.2° C. It is

important that you measure the temperature of the silver

and not that of the sand. The function of the sand is to

provide an even influx of temperature to the entire area

of the silver and it provides an excellent insulator.

"The temperature of 43.2° C is

optimum under ideal conditions. It is, however, possible

that the temperature may vary within the statistical

limits shown in Table 1. When the temperature is exact

for the reaction the silver with become endothermic.

This means that the temperature will be slightly greater

than that of the surrounding sand. A point of interest -

this reaction is the same as observed in the working

Cold Fusion cells of the past. The scientists were not

observing a low energy nuclear event; rather, they were

observing an inter-dimensional phenomenon.

"Achievement of the maximum

conversion of Ag to Au will depend on the dwell time at

resonance temperature. Conversion of Ag to Au can ocur

in as little as six hours; 2% conversion takes up to 24

hours.

Theory ~ "The conversion

of one element (specifically one isotope) to another

through a dimensional reaction occurs under select

conditions of phonon resonance. Dimensional phonon

resonance occurs when the space occupied by one isotope

is exactly the same as that of another isotope in its

rest state. This event only occur under the following

two conditions: (1) the expansion of an isotope by

heating; or, (2) the contraction of an isotope by

cooling.

"Due to the natural

characteristics of elemental properties, this event is

extremely rare and one can only force the event under

select conditions. To determine the phonon resonance of

an isotope, it is necessary to apply the following

formula:

where d is Density in gm/cm3

,

where d is Density in gm/cm3

,

Na is Avogadro's Constant, and

m is mass.

"By determining the inverse,

one will observe the linear atomic spacing.

"Since the resonance frequency

and spacing is required for all isotopes, the

calculations for most isotopes may be determined:

"When an element is heated or

cooled, the atomic spacing will change proportionally to

the cube of the product of the temperature

(increase/decrease) and the expansion coefficient. To

understand, following is the mathematical model for

determining the linear spacing in reference to

temperature:

where t is the

temperature increase,

St is the standardized temperature, and

Ec is the expansion coefficient

"To place this in perspective,

to determine the exacting temperature for a dimensional

phonon reaction to occur, requires knowing the starting

element (specifically the isotope of the starting

element if more than one) and the element to be

produced. Once this is known, you can apply the

following formula:

"This will provide the

temperature required within statistical probabilities. A

statistical probability deals with the least significant

digit (LSD) of each variable. In the case of phonon

resonance, this is limited to the density. For example,

the density of Ag is 10.50 gm/cm3. Taking that the

accuracy is ±1 LSD, we can establish a variable

range by applying the following:

Or, +/- 0.0009524

"To place the mathematics in

perspective, following is the calculations for the

conversion of Ag107 to Au:

"To find the most logical

profile requires determining the basic phonon

frequencies of all of the stable isotopes.

Conversion of Al to Au ~

"The conversion of Al to Au is an absolute application

of dimensional science. In this reaction, gold is

produced in its ultra-pure state on a continuous basis.

This procedure may be utilized for most elements. The

basis of this dimensional occurs in the collection of

atomic size particles that form near the resonant metal

(in this case aluminum). Due to the size of the

particles they appear in what normal chemistry would

consider a gas phase. The targeted element (isotope)

forms in its singular state and due to the lack of

energies present. There are insufficient energies to

bind the atoms into a colloidal state.

"In the production of gold from

aluminum, the ideal temperature is 302.9° C. These

temperatures are optimum for the Al (the Al must be

allowed to come into equilibrium with the furnace). Once

resonance is established, production is continuous. The

Au is captured in water as it is removed from a negative

pressure applied to the furnace established by the

vacuum pump. However, please be aware that Al will also

convert to Ag107 at a temperature of 283.7°

C. To understand this, the following chart is supplied:

"The aluminum reaches the

phonon resonance of Au it passes through the resonance

of Ag. Due to the atomic spacing, Al will not form any

other element near this temperature range.

"All of the procedures listed

were confirmed by independent laboratory testing..

"At the time of printing the

Phonon Conversion of Ag to Au, the genesis mapping of

elements was not complete. Based on the above, the

following allows the other potential formation patterns

for Ag and Au:

z ~ e ~ D gm/cm3 ~ M

~ % abundance ~ Hz ~ phonon spacing/cm3

13 ~ Al27 ~ 2.6989 ~ 26.981 ~ 100.00% ~ 39,200,637 ~

2.55098E-08

47 ~ Ag109 ~ 10.5 ~ 108.904 ~ 48.16% ~ 38,722,676 ~

2.58247E-08

47 ~ Ag107 ~ 10.49 ~ 106.905 ~ 51.84% ~ 38,950,170 ~

2.56738E-08

79 ~ Au197 ~ 19.3 ~ 196.967 ~ 100.00% ~ 38,931,830 ~

2.56859E-08

"This procedure is nondescript.

As easily as zinc, aluminum, titanium or silver converts

into gold, so does gold convert into titanium and

silver."

In 1997, Champion reported the

replication of one of his transmutation experiments by a

16-year old high school student for a science fair

project. The original experiment was performed by Dr

Bockris at Texas A.M. University (www.transmutation.com/tamu.htm).

The ingredients of the experimental formula were:

300 gr Carbon; 900 gr

Potassium Nitrate; 80 gr Sulfur; 100 gr Iron Sulphate;

30 gr Cadmium; 100 gr Mercury Chloride; 50 g r

Litharge (PbO); 5 gr Silver (Ag); 30 gr Calcium Oxide.

The ingredients were mixed, placed in a coffee can, and

ignited with a torch. The silver increased from 5 to 8.7

grams, and a small amount of gold also was produced.

X-ray flourescence and mass spectrometry examinations

were made of the materials before and after the

ignition.

Joe Champion

(10) References

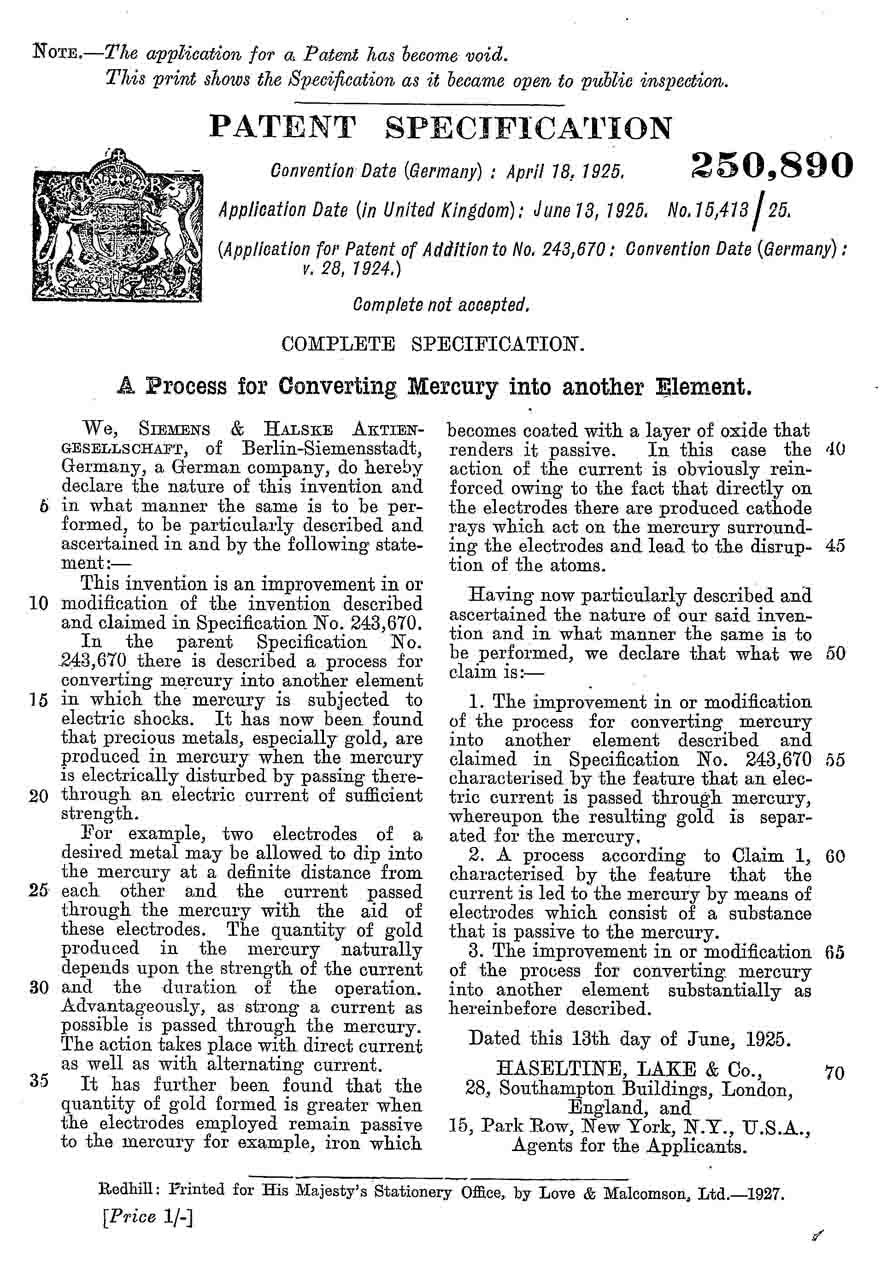

1. "A.A.E.": Nature

121 (# 3060), p. 981 (June 23, 1928)

2. "A.C.": Chimie et

Industrie, (1927), Suppl. 18/19 (4).

3. Anonymous: Rev.

Ind. Chimie Industrielle 37: 63 (1928)

4. Ridpath, J.C.: The

Arena (Boston) 19(1): 139-140 (1898); "The Age of

Gold"

5. Baskerville, C.:

Popular Science Monthly 72 (1): 46-51 (1908); "Some

Recent Transmutations"

6. Bolton, Henry C.:

Chemical News 76: 61-62 (6 August 1897); "The

Revival of Alchemy"

7. Emmens, Dr. Stephen

H.: Chemical News 76: 117-118 (3 September 1897);

The Engineering & Mining Journal 62 (10): 221,

222 (5 September 1896); "The Transmutation of Silver

into Gold"; ibid., 62 (11): 243, 244 (12 Sept.

1896); Emmens, "Transmutation of Ag into Au"; ibid.,

62 (14): 315, 316 (3 Oct. 1896); "The Transmutation of

Ag into Au"

8. Emmens, Dr. S. H.:

Science 5 (112): 314, 315 (19 Feb. 1897); ibid.,

5 (113): 343-344 (26 February 1897); "The

Argentaurum Papers No. 1, Some Remarks Concerning

Gravitation"

9. Emmens, Dr. S. H.:

Argentaurana ; G. Du Boistel (Bristol, 1899).

10. Emmens, Dr. S. H.:

Science 7 (168): 9, 386-389 (18 March 1898); "The

Age of Gold -- A Rejoinder"

11. Emmens, Dr. S. H.:

Arcanae Naturae (Paris, 1897)

12. Emmens, Dr. S. H.:

Argentaurum Papers #1: Some Remarks Concerning

Gravitation; Plain Citizen Publ. Co. (New York,

1896)

13. Fletcher. E. A.:

Frank Leslie's Popular Magazine (March 1898)

14. Fulcanelli: Les

Demeures Philosophales, vol. 1, p. 184-185, 189-200;

J. Pauvert (Paris, 1964)

15. Fyfe, H. C.:

Pearson's Magazine (March 1898)

16. Gaddis, V. H.:

American Mercury 86: 65-69 (January 1958)

17. Jollivet-Castelot,

Francois: Chimie et Alchimie; E. Noury (Paris

1928)

18. Jollivet-Castelot,

Fr.: La Fabrication Chimique de L'Or (Douai,

1928)

19. Jollivet-Castelot,

Fr.: L'Hyperchimie (Paris, 1896-1901)

20. Jollivet-Castelot,

Fr.: La Synthese de L'Or; H. Daragon (Paris,

1909)

21. Lea, Carey: Amer.

Sci. J. (Series 3) 37 (222): 476-491 (June 1889);

ibid., 38 (223): 47-50 (July 1889); ibid., 38

(224): 129 (August 1889); Ibid., 38 (225):

237-241 (September 1889); ibid., 41 (243):

179-190 (March 1891); ibid., 42 (250): 312-317

(October 1891); ibid.,48 (148): 343 (October

1894); ibid., 51 (24): 259-267 (April 1891);

ibid., 51 (246): 282-289 (April 1891).

22. Lea, C.: Zeit.

Anorg. Allgem. Chem. 7: 340-341 (1894)

23. MacKenzie, J.:

Spokane Mines & Electrician (17 February 1897)

24. Ord, W. E.:

Knowledge 20: 285 (1 December 1897)

25. Tiffereau. Theodore:

Les Metaux Sont Des Corps Composes; Vaugirard

(Paris, 1855)

26. Tiffereau, T.:

L'Or et le Transmutation des Metaux

27. Tiffereau, T.:

Comptes Rendu Acad. Sci. Paris 38: 383, 792, 942

(854); ibid., 39: 374, 642-644, 743, 1205 (1854);

ibid., 40: 1317 (1855); ibid., 41: 647

(1855); ibid., 123: 1097 (1896)

28. Waite, Arthur E.:

A Collection of Alchymical Processes; S. Weiser (New

York, 1987)

29. Woodward, Dr. R. S.:

Science 5 (112): 343-344 (19 February 1897)

30. Young, C. A.:

Science 5 (113): 343-344 (26 February 1897)

Over 150 megabytes online of information on

alchemy in all its facets. Divided into over 2400

sections and providing tens of thousands of pages of

text, over 2500 images, over 240 complete alchemical

texts, extensive bibliographical material on the

printed books and manuscripts, numerous articles,

introductory and general reference material on

alchemy.

Over 150 megabytes online of information on

alchemy in all its facets. Divided into over 2400

sections and providing tens of thousands of pages of

text, over 2500 images, over 240 complete alchemical

texts, extensive bibliographical material on the

printed books and manuscripts, numerous articles,

introductory and general reference material on

alchemy. Join the mailing list

Join the mailing list

Alchemy Web Bookshop

Alchemy Web Bookshop

NEW

Exploring alchemical emblems - a course

using audio visual presentations. Click for

sample.

NEW

Exploring alchemical emblems - a course

using audio visual presentations. Click for

sample.

This

website has been substantially supported by Dan Levy

since 1996 by his donation of the space and bandwith

on the

This

website has been substantially supported by Dan Levy

since 1996 by his donation of the space and bandwith

on the